Home > Company News > Common faults and treatment of aluminum melting furnace?

Company News

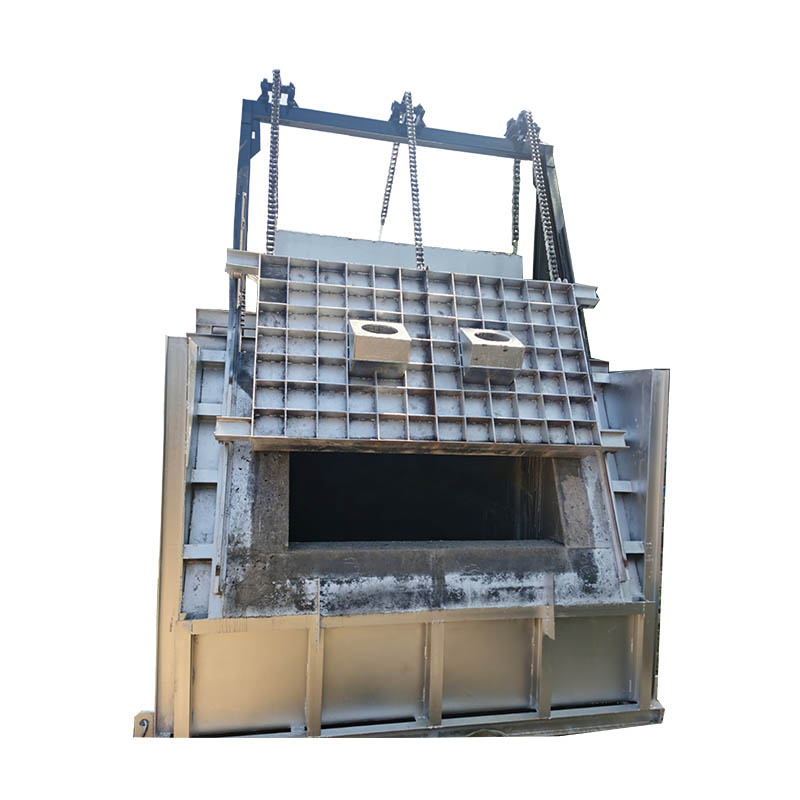

Aluminum melting furnace is a new type of high-efficiency and energy-saving furnace developed according to aluminum melting process. It can well meet the requirements of aluminum melting process.

It can also meet the requirements of strict alloy composition requirements, discontinuous production and large single furnace capacity, so as to reduce consumption, reduce burning loss, improve product quality, reduce labor intensity, improve working conditions and improve production efficiency. It is suitable for intermittent operation and smelting with more gold and reheating materials.

1. First check whether there are foreign matters in the lower aluminum melting furnace. If there is any foreign matter, it needs to be removed immediately. Check whether the feeding shaft is stuck due to excessive feeding during ignition. If so, just reduce the feeding during the ignition process.

2. Check whether the chimney outlet is unobstructed. If it is not unobstructed, clean up the ash in the chimney. Check whether there is ash accumulation between the lower pot and the furnace wall. If there is dust, it needs to be removed immediately. If the fire hole is blocked, sundries need to be removed.

3. Increase or decrease the air supply frequency of aluminum melting furnace and adjust the frequency to normal. Check the bridge of combustion chamber of aluminum melting furnace for coking and clean it.

4. If the whole current board fails, the current board needs to be repaired or replaced. If only the main switch is not turned off, just turn off the main switch. The control power adjustment potentiometer is damaged or short circuited and needs to be repaired immediately. 5. Inverter circuit board and inverter failure. Inverter power system fault, inverter pulse without 22V power supply.

6. In case of poor control of the frequency converter control board, it shall be repaired in time. When the small working angle is not adjusted properly, just adjust the working angle. The aluminum melting furnace is short circuited or grounded, and the voltage circuit can be short circuited at the output side.

-

Yosion Technology YX-CF50 Fire Assay Cupellation Furnace;Ash Blowing Refining;Muffle Furnace

-

Yosion Technology YX-FF25 Fire Assay Melting Furnace;Heating the Sample;Muffle Furnace

-

Molybdenum wire Pure molybdenum wire Molybdenum lanthanum wire

-

Pure molybdenum sheet High temperature molybdenum sheet

-

99.95% Pure molybdenum rod and molybdenum processing workpiece Molybdenum electrode rod

-

High temperature molybdenum plate ≥99.95% Pure molybdenum plate

-

High temperature vacuum furnace molybdenum furnace and molybdenum accessories

-

25kw 35kw 45kw 70kw Medium frequency induction melting furnace

-

20kg 50kg 100kg Induction melting furnace for melting copper, iron and steel

-

Small medium frequency induction melting furnace

-

2024 hot 50kg induction melting furnace

-

Medium frequency induction metal melting furnace